Every morning at 7:00 AM, operations managers across industries face the same question: what should we do differently today? The answer used to come from experience, gut feel, and last month’s report. Now it comes from data. Data analysis transforms raw data into actionable insights, enabling businesses to make well-informed decisions. This process is central to business decision making, as data analysis informs strategic and operational choices by providing evidence-based guidance. Implementing data analytics can lead to cost savings by identifying areas where expenses can be reduced without sacrificing quality. Predictive analytics also supports financial forecasting, helping organizations project future performance and optimize financial strategies.

Data improves operational decision making by transforming how frontline teams handle routing, staffing, inventory, and dozens of other tactical choices. We’re not talking about boardroom strategy sessions or five-year plans. We’re talking about the decisions that happen every shift: which orders to prioritize, how many people to schedule, when to reorder materials, and where to send the next delivery truck. Businesses rely on robust data collection and analytics tools to optimize operations, improve customer engagement, and support strategic decision-making. Data analysis boosts operational decisions by revealing hidden patterns for efficiency and forecasting needs. Data-driven decision-making involves leveraging data sources such as customer feedback, market trends, and financial data to guide the decision-making process. Additionally, data analytics enhances customer satisfaction by enabling businesses to tailor their marketing strategies based on customer behavior. For instance, Coca-Cola utilizes AI-powered data analytics to gain insights into consumer preferences for personalized marketing. Similarly, a global online retailer uses customer data to build targeted marketing campaigns and enhance its recommendation engine. Analyzing customer preferences and customer segments allows businesses to develop targeted products and services that better meet market demands. Utility companies employ data analytics to predict energy consumption patterns accurately, allowing them to optimize energy distribution and reduce waste. Furthermore, analyzing customer complaints helps organizations identify areas for service or product improvement, leading to higher customer satisfaction and operational quality.

Since around 2015, the convergence of cloud ERPs, cheap IoT sensors, and real time analytics has made data central to operations in sectors like logistics, retail, and manufacturing. Efficiently processing data is now essential for feeding analytics, machine learning models, and decision-making systems. Consider a UK retailer during Black Friday 2024: using POS data refreshed every 15 minutes, store managers adjusted in-store staffing and triggered shelf replenishment before stockouts occurred. That’s data driven decision making in action—not abstract analysis, but immediate operational response. Data analysis helps identify slow periods to launch targeted promotions, increasing overall sales. Walmart, for example, uses data analytics to monitor customer shopping patterns and optimize inventory levels, ensuring products are available when and where they are needed.

So what exactly is operational decision making? It’s the tactical, daily and weekly choices about production, workforce, service levels, and resource allocation. These decisions are distinct from strategic choices like entering new markets or acquiring companies. Operational decisions are higher frequency, closer to the customer, and far more numerous. Aligning data analysis with business goals ensures that operational decisions drive strategic success and support organizational objectives. The rest of this article will show you how data improves these decisions through better visibility into what’s happening now, faster response times when conditions change, greater consistency across shifts and sites, meaningful cost reduction through waste elimination, and smarter risk management that catches problems early. Many organizations struggle to make their data actionable, which is a common hurdle in data-driven decision-making. However, confirmation bias can skew data analysis, leading to biased outcomes if decision-makers selectively interpret data to support preconceived notions. Extracting data insights and leveraging data-driven insights are crucial for improving business outcomes and fostering a culture of continuous improvement.

Data analysis reveals hidden patterns and trends that might otherwise go unnoticed. Organizations transform raw data and focus on turning raw data into actionable insights, enabling better decision making and operational efficiency.

Table of Contents

ToggleWhat is data-driven operational decision making?

Data-driven operational decision making means using timely, quantified information from operational systems—ERP, MES, WMS, CRM, telematics, and more—to decide who does what, when, where, and with which resources. Data-driven decision-making strategies allow business leaders to make decisions faster and using fewer resources. Logistics companies optimize delivery routes using real-time traffic, weather, and GPS data, improving on-time delivery rates. Hyper-personalization uses behavior tracking to offer real-time personalized product recommendations, further enhancing operational efficiency.

This isn’t about running sophisticated analyses once a quarter. It’s about embedding data into standard operating procedures: shift planning, routing decisions, quality checks, purchasing triggers, and maintenance scheduling. When a warehouse supervisor decides how many pickers to assign to the afternoon shift, that decision should be informed by historical data on order volumes, not just intuition. Data analytics enables businesses to gain deep customer insights, allowing for personalized products and services. For instance, Netflix employs data analytics to generate content recommendations based on user viewing data, demonstrating the power of data in creating tailored experiences. Similarly, a major streaming video service uses data analytics to inform aspects of its content creation and market expansion process, ensuring alignment with audience preferences. Furthermore, data analytics can enhance product development by analyzing customer feedback and market trends to create innovative solutions that meet evolving consumer needs.

The data types that drive these decisions are recognizable to anyone in operations: sensor readings from production lines, order lead times from the past 12-24 months, call center handle times by hour of day, on-time delivery percentages by carrier and region, and customer satisfaction scores by product category.

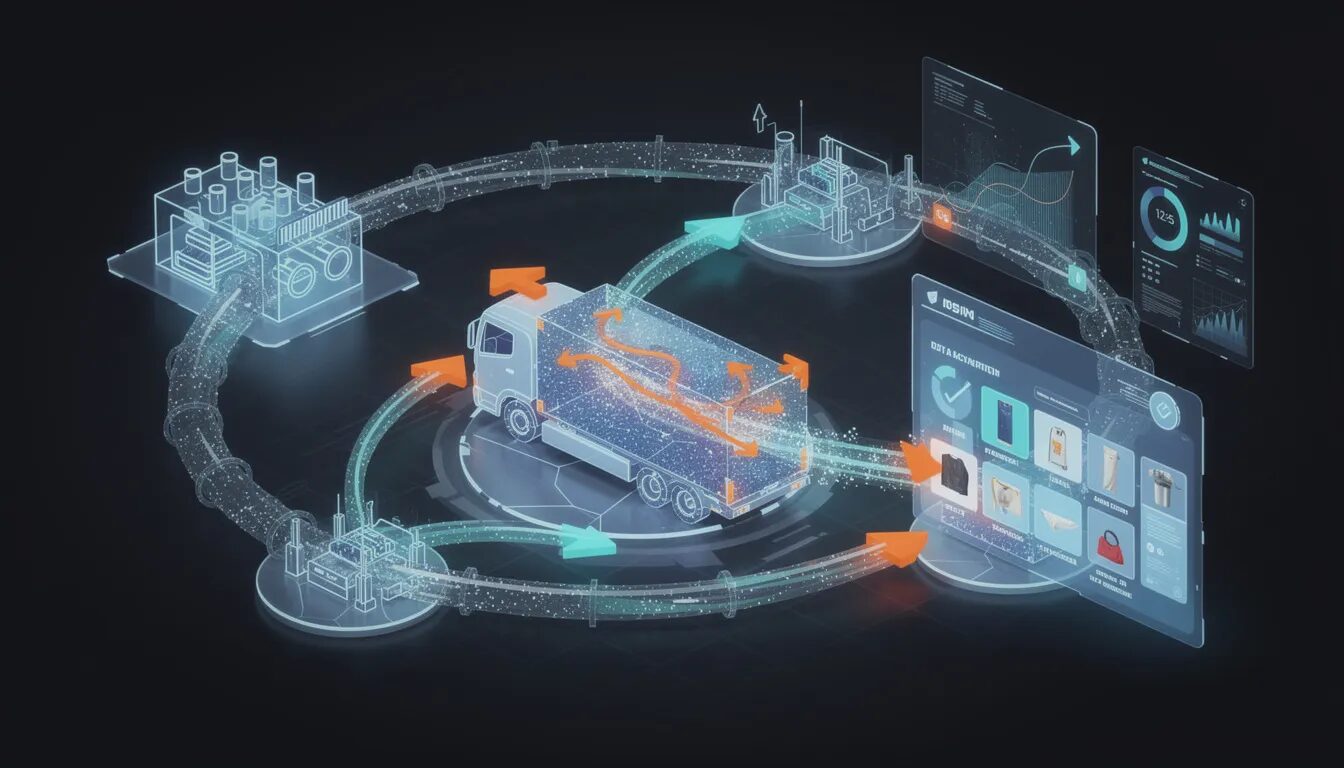

The data pipeline follows a repeatable pattern: capture raw data from operational systems, clean and validate it, aggregate it into meaningful metrics, visualize it in dashboards, use it to inform decisions, act on those decisions, then measure the impact and refine the approach. Implementing data integration solutions is essential to overcome the challenge of data residing in disparate systems and formats across departments. Neglecting data security poses risks, as protecting data from breaches and ensuring compliance with data privacy regulations is essential for maintaining trust and operational integrity. Additionally, data analytics supports better financial management by improving forecasting and helping to make informed budget decisions, enabling organizations to allocate resources more effectively.

Research from McKinsey, Gartner, and other analysts has consistently found since 2020 that firms using operations analytics are significantly more likely to outperform on cost and service-level KPIs. This isn’t theoretical—it’s been proven across industries and company sizes. Organizations that adopt a data-driven culture see benefits such as improved customer satisfaction, better strategic planning, and more. Overreliance on historical data can be problematic, as it might not accurately predict future trends in rapidly changing environments. Data illiteracy is often a critical challenge, as employees may lack the necessary skills to interpret and use data effectively.

Key operational areas where data improves decisions

Saying “data is important” doesn’t help anyone schedule a shift or plan a production run. What matters is understanding exactly where in the business data analytics actually changes daily decisions.

The following sections walk through specific operational domains—inventory, production, workforce, logistics, customer service, and quality—with concrete examples from 2019-2024. For each area, you’ll see measurable impacts in realistic ranges (10-30% improvements, not vague promises) and learn how combining historical data with real time data feeds creates the most value.

Inventory and supply chain planning

Supply chain optimization starts with better demand forecasting. Retailers and manufacturers use 2-3 years of historical sales data, seasonality patterns, and promotion calendars to forecast demand at the SKU-store or SKU-plant level. This historical data provides the foundation for every reorder and safety stock decision.

A grocery chain, for example, might combine sell-through data from 2022-2024 with weather forecasts to pre-position ice-melt, bottled water, and canned goods before storms hit a region. That’s leveraging data analytics to turn raw data into actionable insights—and it happens days before the first snowflake falls.

Key inventory decisions driven by data include:

- Reorder points and safety stock levels calculated from lead time variability, supplier reliability scores, and forecast error rates

- Slow-moving stock identification through dashboards that highlight low-turn items, prompting decisions to discount, bundle, or discontinue

- Supplier selection based on on-time-in-full (OTIF) performance tracked over the past 12-18 months

- Demand sensing using point-of-sale data, web traffic, and market trends to adjust forecasts weekly rather than monthly

The relevant KPIs include stockout rate, inventory turnover days, supplier OTIF percentage, and forecast accuracy (typically measured as MAPE or bias). Organizations that get this right typically see 15-25% reductions in working capital tied up in inventory while simultaneously reducing stockouts.

Production scheduling and manufacturing efficiency

Factories use MES (Manufacturing Execution Systems) and SCADA data to decide which orders run on which lines, in what sequence, and when to switch over. These aren’t annual planning decisions—they happen every morning.

Consider an automotive supplier that adjusts its daily production plan at 7:00 AM using three data inputs: current order backlog and priority, machine status and availability from overnight, and workforce availability including absences and skill certifications. By 7:30 AM, supervisors know exactly what each line will produce that day.

Real time data from the production floor feeds Overall Equipment Effectiveness (OEE) metrics covering availability, performance, and quality. When the data shows a bottleneck machine running at 68% OEE while others are at 85%, planners know where to focus improvement efforts.

Data on changeover times and scrap rates helps planners sequence product variants to minimize downtime. If switching from Product A to Product B takes 45 minutes but A to C takes only 15 minutes, the data drives the sequencing decision.

Predictive maintenance represents one of the clearest wins for data in manufacturing. Vibration and temperature sensors predict failures days in advance, transforming maintenance scheduling from fixed calendars to data-driven interventions. Organizations report 20-30% reductions in unplanned downtime when they move to predictive approaches.

Workforce and shift planning

Call centers, warehouses, and hospitals all face the same challenge: matching staff capacity to variable demand. Data analytics makes this matching far more precise.

A European e-commerce warehouse uses historical order volumes from 2019-2024 plus marketing campaign calendars to set staffing levels for the upcoming week. If a flash sale is scheduled for Thursday, the data shows how similar past sales affected pick volumes by hour, allowing managers to schedule accordingly.

Workforce decisions informed by data include:

- Shift start times and lengths aligned to predicted demand curves

- Overtime approval thresholds based on cost-per-unit calculations and SLA risk

- Temporary worker allocation triggered when forecasted volume exceeds permanent capacity

- Task assignment using skill-level data (pick rates, call resolution rates) to match complex tasks with capable workers

The benefits are measurable: lower overtime costs (often 10-20% reduction), fewer service-level breaches, and reduced employee burnout from more accurate staffing. When you know how many calls will come in at 2:00 PM on a Tuesday, you can staff for that reality rather than guessing.

Logistics, routing, and last-mile delivery

Routing engines combine GPS data, telematics, and order management information to design daily delivery and pickup routes. The decisions involved—which orders ship from which warehouse, how to consolidate loads, whether to use same-day or next-day service—all depend on cost-to-serve data.

A parcel carrier in 2023 faced peak season with a data-driven approach: real time traffic data fed into routing algorithms, parcel volumes updated every 30 minutes, and driver hours-of-service rules enforced automatically. When a highway closed unexpectedly, coordinators re-routed affected vans within minutes, not hours.

The KPIs that matter include on-time delivery percentage, average distance per stop, fuel cost per delivery, and first-attempt delivery success rate. Companies tracking these metrics can simulate alternate routing or carrier choices before committing, choosing the scenario that best balances cost and customer satisfaction.

The competitive edge in logistics comes from making thousands of small routing decisions correctly each day, not from one brilliant strategy.

Customer service operations

Contact centers generate enormous amounts of data: call volumes by time of day, handle times by issue type, abandonment rates by queue, and resolution rates by agent. This data collection enables decisions that directly affect customer experience.

A telecom operator analyzed daily data from 2022-2024 to identify peak complaint topics—billing confusion spiked on the 5th of each month when statements arrived. Armed with this insight, they prioritized self-service articles on billing, adjusted IVR messaging, and scheduled their best billing specialists for those days.

Routing decisions in customer service are increasingly data-driven: which calls go to first-line agents versus specialists depends on customer behavior patterns, value scores, and past interaction history. When a high-value customer calls with a complex issue, the data routes them to a senior agent automatically.

Speech analytics and sentiment scores extracted from customer interactions inform coaching plans and script adjustments. If a particular script is generating negative sentiment in 40% of calls, that’s a decision trigger for the training team.

The measurable benefits include improved first-contact resolution (FCR), shorter average handle time (AHT), and higher Net Promoter Score (NPS)—all tracked through business intelligence tools that surface these metrics daily.

Quality control and risk management

Factories and service organizations use defect logs, returns data, and incident reports to decide where to tighten quality checks. This is risk management in action: using data to focus resources where problems actually occur rather than spreading controls everywhere.

A food manufacturer from 2021-2024 used batch-level quality data to make critical decisions: which lots to quarantine for additional testing, which to expedite to market, and—in rare cases—which to recall. Without that granular data, every batch would require the same expensive testing.

Statistical process control (SPC) charts and automated alerts trigger decisions when a process drifts outside control limits. An operator sees a trend line approaching the upper control limit and decides to adjust machine settings before producing defective product.

For operational risk more broadly, near-miss data and safety incident trends inform decisions about which sites receive additional training or audits. Financial institutions using data-driven risk assessment models have reportedly reduced exposure to losses by up to 35% while still meeting growth targets—a prime example of how analyzing data creates business success. Additionally, financial institutions use advanced machine learning algorithms to detect and prevent fraud, further enhancing their ability to manage risks effectively.

From intuition to evidence: how data changes the decision process

Operational decisions were historically made on experience, gut feel, and monthly paper reports. A distribution center manager in 2018 might decide on staffing by thinking “Mondays are usually busy” and adding a few extra people. That same manager in 2024 pulls up a dashboard showing order forecasts by hour, compares it to available capacity, and makes a data-backed decision.

The modern decision cycle follows a repeatable pattern:

- Define the question: What specific decision needs to be made? (e.g., how many pickers for Monday morning?)

- Pull relevant data: Historical volumes, forecasts, current backlog, available staff

- Analyze and visualize: Compare predicted demand to capacity, identify gaps

- Compare options: Three scenarios—baseline staffing, add overtime, call temps

- Decide: Choose the option with best cost/service tradeoff

- Implement: Schedule confirmed, staff notified

- Measure outcome: Track actual vs. predicted volumes and service levels

- Refine rules: Adjust thresholds for next cycle

Decision rules that were once arbitrary guesses are now derived from past data. “If backlog exceeds 2,000 orders by 6:00 AM, open an extra packing line” becomes a rule because data analysis showed that threshold correlates with SLA breaches.

This doesn’t mean algorithms make all the decisions. People still make the final call—data reduces uncertainty and bias rather than replacing human judgment. The supervisor who sees the data recommending overtime can still override it if they know something the data doesn’t (a key team member’s unusual availability, for example).

Building the data foundation for operational decisions

Effective operational decisions depend on accessible, accurate, and timely data from core systems. Without the right foundation, even the best analytics tools produce unreliable insights. Internal data sources include CRM, ERP, and financial statements, while external data sources encompass market research and social media.

The foundation starts with standardizing key operational metrics and definitions across sites. What counts as “on-time”? Is it delivery by promised date or by promised hour? What qualifies as a “defect”? These definitions must be consistent for data to inform business decisions meaningfully.

Common data sources include:

| Source Type | Examples | Update Frequency |

|---|---|---|

| Transactional systems | ERP orders, WMS picks, TMS shipments | Real-time to hourly |

| Sensors and IoT | Machine temperatures, vibration, GPS | Seconds to minutes |

| Workforce systems | Time clocks, skill databases, schedules | Daily |

| Customer systems | CRM interactions, tickets, feedback | Real-time to daily |

| External data | Weather, competitor pricing, traffic | Hourly to daily |

These data sources come together in a data warehouse or data lakehouse where they can be queried, joined, and analyzed. Data quality routines—deduplication, anomaly detection, handling missing values, reconciling records between systems—are essential for maintaining trust in the numbers.

For operations where minutes matter—same-day delivery, 24/7 production lines, high-volume contact centers—near real time data pipelines are necessary. Waiting until tomorrow to see today’s data means missing the window to act.

Practical techniques and tools for data-driven operations

Operations teams don’t need to become data science experts to benefit from data analytics. The goal is to put practical, easy-to-understand tools in the hands of people making decisions every shift.

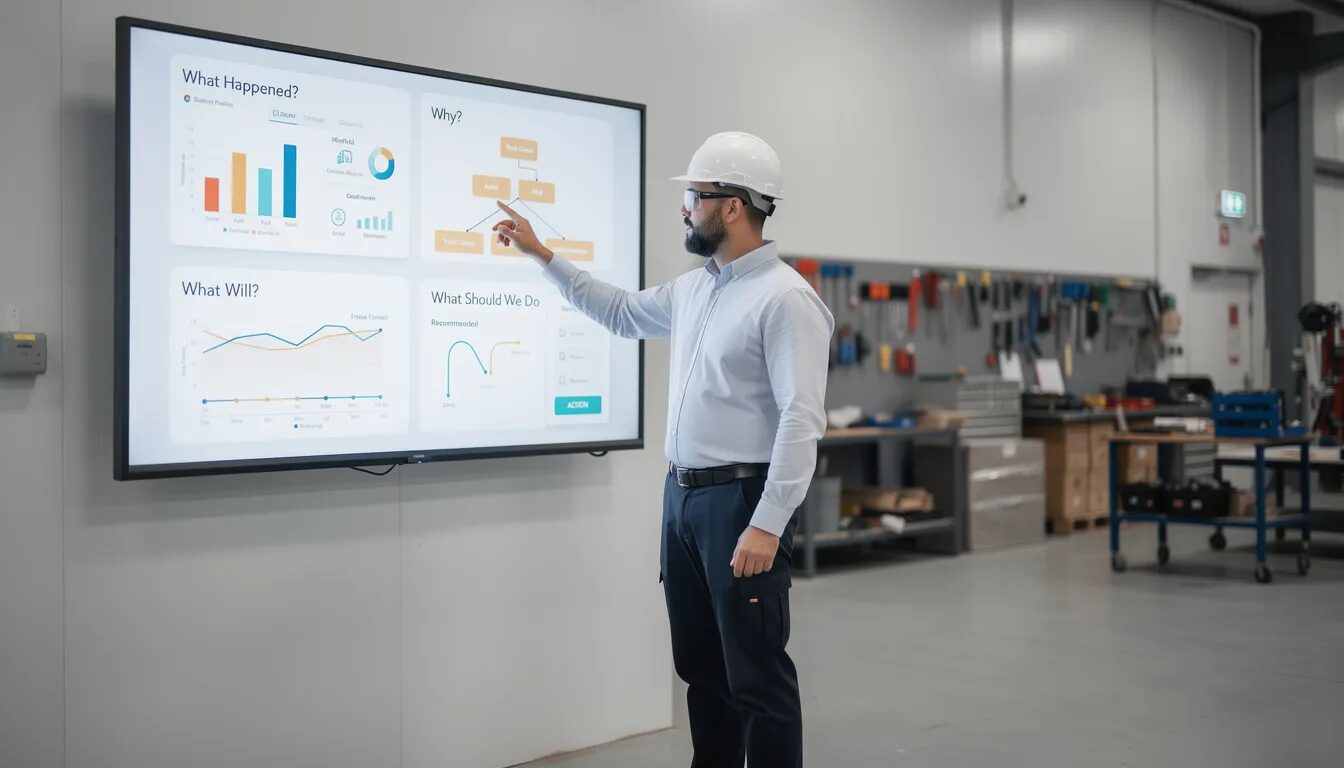

The techniques range from descriptive analytics (“what happened?”) through diagnostic (“why?”), predictive (“what will happen?”), and prescriptive (“what should we do?”). Each serves a different decision need, and many capabilities are now available in mainstream platforms like Microsoft Power BI, Tableau, Qlik, and cloud ERP analytics modules—no large data science team required.

Descriptive and diagnostic analytics for operations

Descriptive analytics summarizes what happened yesterday, last week, or last month: volumes processed, cycle times achieved, errors encountered, backlogs remaining, and resources utilized. This transforms raw data into actionable information.

Standard operational dashboards display key performance indicators like order cycle time, fill rate, machine utilization, and queue length—all broken down by site, shift, product line, or team. These dashboards give supervisors immediate visibility into performance.

Diagnostic analytics answers “why did it happen?” using drill-downs, Pareto charts, and root-cause analysis. If pick errors spiked last Tuesday, diagnostic analysis might reveal that 60% of errors occurred in aisle 7, primarily during the evening shift, with three specific pickers responsible.

This insight supports concrete decisions: redesign aisle 7 layouts, provide additional training for those pickers, or investigate whether a labeling issue is confusing workers. Data interpretation leads directly to action.

Predictive analytics and forecasting in daily operations

Predictive analytics uses historical patterns—often 3-5 years of past data—plus current signals to forecast near-term demand, workload, or failure probabilities. This is where machine learning models increasingly add value.

Applications include:

- Predicting tomorrow’s call volume by 30-minute interval to set staffing levels

- Forecasting which machines will likely fail in the next 72 hours based on sensor trends

- Anticipating customer demand spikes from web traffic and weather patterns

- Estimating which orders are at risk of missing SLAs based on current progress

These forecasts guide decisions: opening extra checkout lanes, scheduling preventive maintenance, ordering materials earlier, or pausing promotional campaigns that would overwhelm fulfillment capacity.

A retailer that adopted machine learning models for demand forecasting improved accuracy by 25%, leading to fewer stockouts and fewer costly emergency shipments. Even simpler statistical models—moving averages, exponential smoothing—deliver significant improvements when consistently applied to turn data into actionable insights.

Prescriptive analytics and scenario simulation

Prescriptive analytics recommends specific actions given constraints and objectives. Rather than showing “here’s the forecast,” it shows “here’s what you should do about it.”

Operations planners can run “what-if” scenarios: What happens if a key supplier fails? If a shift is canceled due to weather? If a promotion doubles expected demand? Each scenario generates alternative plans with projected outcomes.

For example, a production planner might compare three scheduling options for the week:

| Scenario | Overtime Hours | Units Produced | On-Time % | Total Cost |

|---|---|---|---|---|

| Baseline | 120 | 48,000 | 91% | $142,000 |

| Add temp shift | 40 | 52,000 | 97% | $148,000 |

| Expedite materials | 80 | 50,000 | 94% | $151,000 |

The goal isn’t perfect prediction but better comparative decisions between realistic options. Many modern cloud ERPs and planning systems now include this functionality for mid-sized businesses, putting prescriptive capabilities within reach of organizations that couldn’t afford custom optimization software.

Dashboards, alerts, and real-time visibility

Visual management screens on shop floors, in control rooms, and at operations desks show real time data in simple, color-coded formats. Green means on track, yellow means watch closely, red means act now.

Practical alerting rules trigger SMS or app notifications when key metrics cross thresholds: queue length exceeds 50 calls, machine temperature rises above 85°C, or a high-priority order is at risk of missing its SLA.

A logistics control tower might display a live map with late shipments highlighted in red. Coordinators can immediately decide on re-routing, customer communications, or carrier escalation without waiting for an end-of-day report.

Dashboards should be understandable at a glance. If operations staff need an analyst to interpret them, they’re too complex.

These tools help shift operations from reactive firefighting to proactive management—seeing problems develop in time to prevent them rather than learning about failures after the fact.

Creating a data-driven operations culture

Technology alone doesn’t change decisions. Frontline supervisors, planners, and operators must trust and use the data for it to matter. Building a data driven culture requires deliberate effort. Providing ongoing training and fostering a data-literate culture is vital for maximizing the benefits of data-driven approaches. Highlighting the significance of ongoing learning and improvement in data-driven culture motivates employees to give feedback on data processes and systems, ensuring continuous refinement and better adoption of data-driven practices. Additionally, data analytics can improve human resources management by providing insights into employee satisfaction and retention rates, enabling organizations to address workforce challenges proactively.

Leadership sets the tone. When plant managers, warehouse heads, and service leaders consistently ask “what does the data say?” in daily stand-ups and weekly reviews, teams learn that data matters. When leaders make decisions visibly based on evidence, that behavior cascades.

Training doesn’t need to be complex. Simple, targeted sessions for supervisors and team leaders focusing on reading charts, understanding variation, and questioning suspicious numbers build the data literacy needed to interpret data effectively.

Incentives reinforce behavior. Recognition programs that reward teams for using data to improve specific KPIs—reducing rework by 15% between Q2 and Q4 2024, for example—show that data-driven improvements are valued.

Feedback loops are essential. Frontline staff often spot data quality issues first—incorrect scans, wrong timestamps, missing records. When they can flag these problems and see them fixed, they trust the data more and use it more.

Embedding data into daily routines and governance

Concrete practices make data use habitual:

- Daily huddles reviewing yesterday’s KPIs on a visible board or screen

- Weekly performance reviews examining trend charts and identifying exceptions

- Monthly root-cause sessions for recurring issues, using data to identify patterns

Every recurring operational decision should have a documented data input and clear guideline. Shift start decisions reference volume forecasts. Reorder decisions reference inventory levels and lead times. Carrier selection decisions reference historical OTIF scores. Resource optimization can lead to efficiency improvements of up to 20% by identifying bottlenecks in production or logistics. Creating open data-sharing methods and platforms allows employees to access suitable data sets and insights to guide their decisions, fostering a more collaborative and informed decision-making environment.

Simple data governance establishes who owns each KPI, who can change decision rules, and how changes are tested before rollout. A company that standardized its operations scorecards across multiple sites in 2023-2024 could finally compare performance apples-to-apples and identify best practices to share.

Start with pilot projects on a single site or process to demonstrate value before scaling. Quick wins build credibility for broader data initiatives.

Common pitfalls and how to avoid them

Many data-for-operations projects underdeliver because they focus on technology rather than specific decisions. Buying a dashboard tool doesn’t improve operations—connecting that tool to actual decisions does.

Common pitfalls include:

| Pitfall | What Goes Wrong | How to Avoid |

|---|---|---|

| Irrelevant metrics | Dashboards track things nobody acts on | Start from decisions, work backward to required data |

| Lagging data | Information arrives too late to matter | Invest in real time analytics for time-sensitive decisions |

| Poor data quality | Garbage in, garbage out | Implement data governance and validation routines |

| Analysis without action | Reports generated but never used | Assign owners to every metric with clear response expectations |

| Over-complex models | Frontline staff can’t understand outputs | Keep models simple enough for operators to trust and question |

“Vanity dashboards” look impressive but map to no operational decision and have no owner. Before building any report, ask: “What decision will this inform? Who will make that decision? How often?”

The best approach is iterative: identify a specific recurring decision (how many pickers to schedule Monday), design data and analytics just for that decision, measure impact, then expand. Small improvements compound into significant operational efficiency gains over time.

Conclusion: why data-driven operations win

Data improves operational decision making by increasing visibility into what’s happening, accelerating response times, creating consistency across sites and shifts, reducing costs through better resource allocation, and managing risks before they become crises. Organizations can change more easily to fit different market situations and trends when they have a data-driven culture, as it fosters adaptability and responsiveness to external changes. This flexibility ensures that businesses remain competitive and resilient in dynamic environments.

The domains covered—inventory and supply chain planning, production scheduling, workforce planning, logistics and routing, customer service operations, quality control and risk management—represent where most organizations can find immediate value. Each domain offers opportunities for informed decisions that add up to meaningful competitive advantage.

The key benefits don’t come from one brilliant algorithm or a single transformative insight. They come from thousands of small, better decisions every day. When every shift supervisor, planner, and team leader makes slightly better choices because they have better data, the cumulative impact on business objectives is substantial.

Here’s what to do next: pick one or two high-impact operational decisions in your own organization—maybe staffing levels, reorder timing, or route planning—and start instrumenting them with better data within the next 90 days. Measure results. Refine the approach. Expand from there.

By 2026 and beyond, organizations that master data-driven operations will be more resilient to supply shocks, labor shortages, and demand volatility than those that don’t. The question isn’t whether data will reshape operations—it’s whether your organization will lead that change or react to competitors who did.

Data collection and machine learning in operations

In today’s data-driven business environment, effective data collection is the cornerstone of operational efficiency. Organizations that systematically gather raw data from every aspect of their operations—whether it’s production line sensors, transaction logs, or customer interactions—are better positioned to leverage data analytics for continuous improvement. By transforming raw data into valuable insights, companies can identify trends, monitor key performance indicators, and make informed decisions that drive operational efficiency.

Machine learning has become a game-changer in this landscape. By applying machine learning models to historical data, businesses can uncover hidden patterns and predict future outcomes with remarkable accuracy. For example, financial institutions routinely use machine learning to analyze vast amounts of past data, enabling them to forecast market trends, assess risk, and make data-driven decisions that minimize exposure. In the supply chain, real time analytics powered by machine learning allow companies to monitor inventory levels, track shipments, and respond instantly to fluctuations in customer demand.

The benefits of integrating data collection and machine learning into operations are clear: processes become more agile, customer satisfaction improves through faster and more accurate responses, and organizations gain a competitive edge by anticipating market shifts before they happen. By leveraging data analytics and machine learning, businesses can move beyond reactive management to proactive optimization, ensuring that every decision is backed by data and aligned with business objectives.

Future trends in operational decision making

Looking ahead, the future of operational decision making will be defined by the rapid evolution of technologies such as artificial intelligence, big data, and predictive analytics. As organizations generate and store ever-increasing volumes of data, the ability to collect, analyze, and interpret this information will become a critical differentiator. Real time data analysis is set to become the norm, empowering businesses to make swift, data-driven decisions in response to changing market conditions and customer needs.

Another emerging trend is the heightened focus on data governance. Ensuring the quality, security, and integrity of data will be essential for organizations seeking to maintain a competitive edge and build trust with customers and partners. As data governance practices mature, companies will be better equipped to leverage data analytics for strategic advantage.

Descriptive analytics, including the analysis of sales data and customer feedback, will play an increasingly important role in operational decision making. By interpreting these data sources, businesses can identify areas for improvement, optimize processes, and enhance customer satisfaction. Predictive analytics will further enable organizations to anticipate future trends and proactively address challenges before they impact performance.

By embracing these future trends and investing in advanced data analytics capabilities, businesses can unlock new opportunities for growth, innovation, and operational excellence. The organizations that prioritize real time data analysis, robust data governance, and the integration of artificial intelligence into their decision making processes will be best positioned to thrive in an increasingly complex and competitive market.